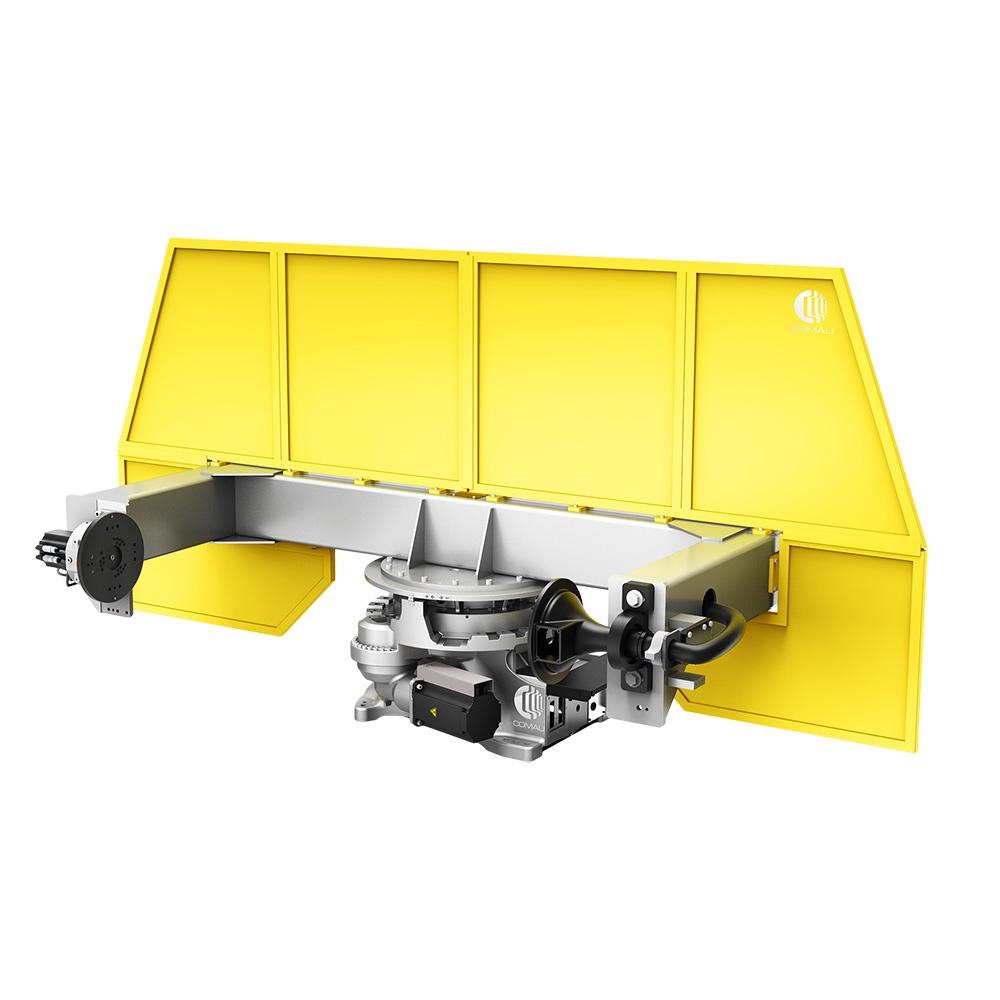

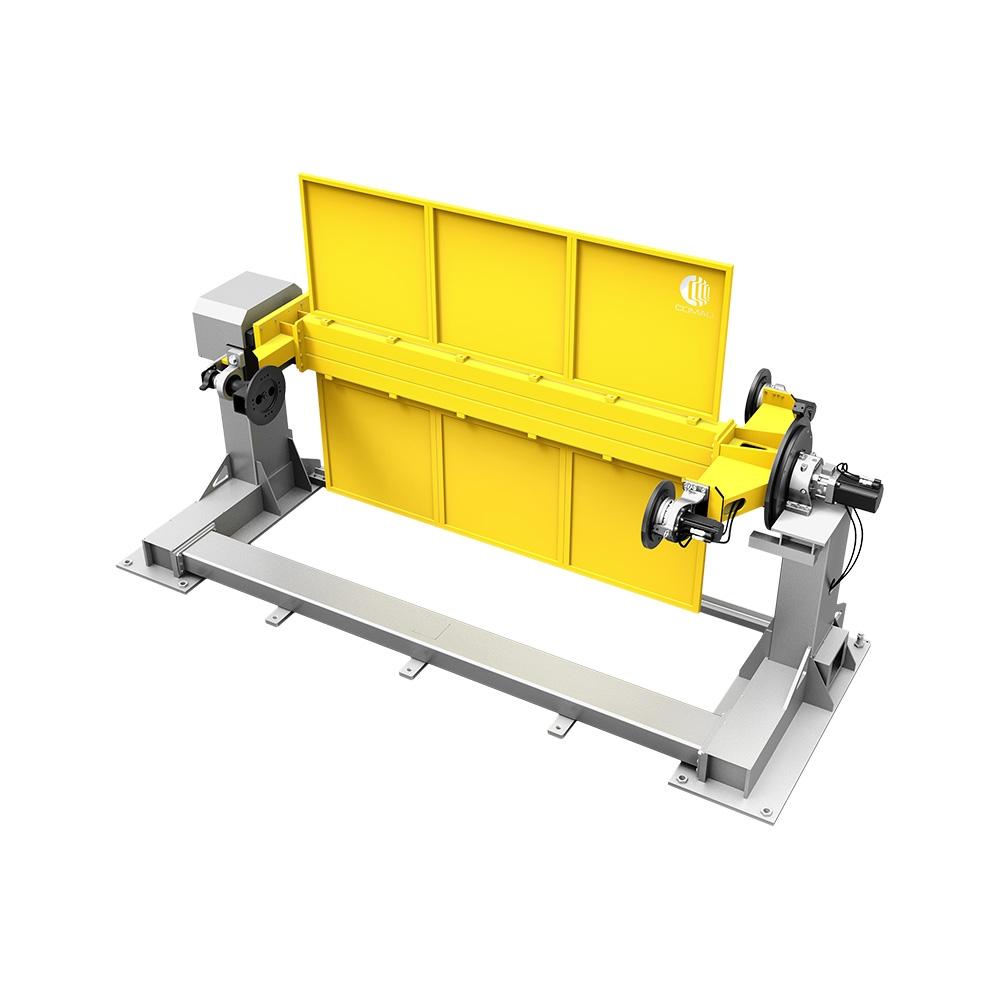

Positioners - TR

Rotary Tables

The TR rotary tables permit the angular positioning of parts during a machining cycle in automated cells, for example.

The part to be machined is to be mounted on a specific fixture provided by the integrator, and fastened to the upper rotating plate of the table.

The table base, secured to the ground, supports the motor and the reducer for the rotation around the rotary table vertical axis.

The rotary table is provided with holes to mount the fixtures used to clamp the parts for machining.

The tables may be supplied complete with servo-controlled motor managed as an additional axis of one of the robots of the Comau robot range, or they can be supplied without the drive unit.

There are two versions to choose from for each of the two tables described above, the MT version (multi turn) or ST(single turn); mechanically the tables differ in operation by the presence of the mechanical limit switch pad.

The TR rotary table is operated by the C5G Control Unit as an additional axes, typically integrated in the standard Control Unit that already manages the Robot.

Payload range: 1000-6000 Kg